Contact us

0119809261

Headquarters

Ring Road, 28 Villafranca Piemonte

Ask for information

info@italcleaneurope.com

0119809261

Ring Road, 28 Villafranca Piemonte

info@italcleaneurope.com

In the early 1970s, the founder of Italclean Europe, began to import and distribute in Italy the self-propelled suction sweepers of a well-known Franco-German brand.

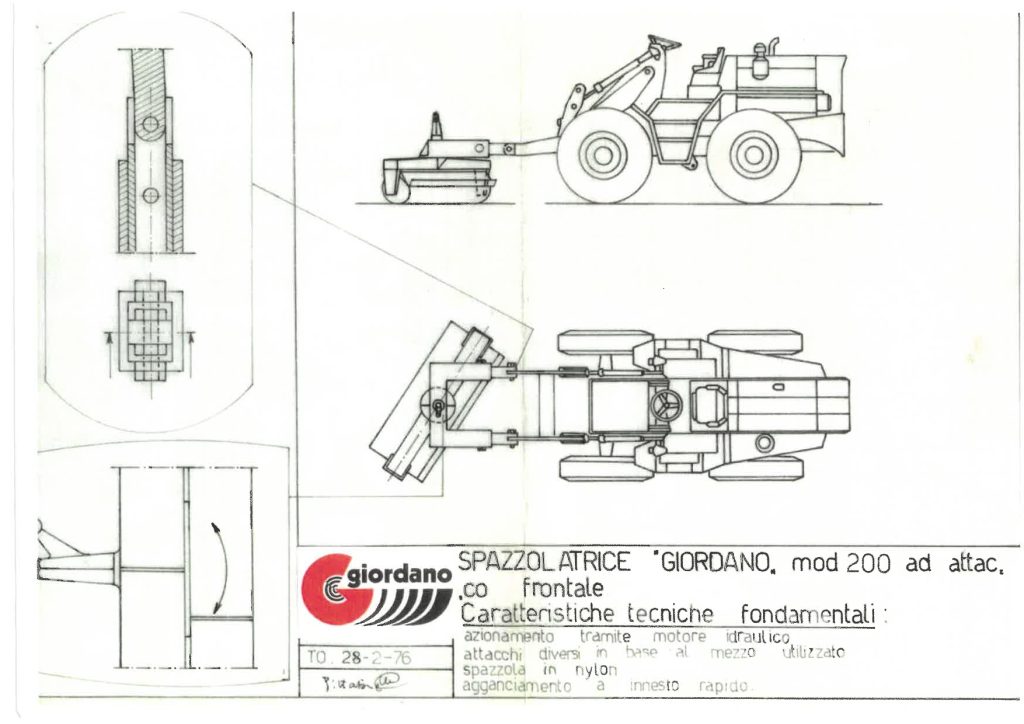

From the visibility obtained, a major Italian construction equipment manufacturer asked us to study and apply a hydraulic angle brushing machine on a their wheel loader. In addition to wheel loaders, the area of use quickly expanded to include: tractors, telehandlers, forklifts, skid loaders trucks, and finally even small garden tractors.

The idea of exploiting an existing means of sweeping immediately sparked such curiosity that in 1976 the first hydraulic angle sweeper was designed and officially unveiled at the 1985 Samoter. Until 1981 the machines were sold under the founder’s trademark, from 1981 until 1993 as Italclean sole proprietorship and then finally transformed into ITALCLEAN EUROPE SRL.

Since then, a story of ingenuity, technology and innovation, in-house research and design, innovative technology, study of operational needs, and expansion of areas of use has continued: these are the guidelines that the founder of Italclean Europe Ltd. has pursued from the beginning to build sweepers and carried sweepers equipped with high quality.

The SPR 120 Series of fully hydraulic mounted suction sweepers were made in 1981. The central brush was available in the following sizes: cm.120 x 37, and the debris collection was separate from the intangible dust.

The vacuum system (with high-performance turbine and synthetic fabric pocket filter unit with hydraulic filter shaker) ensured perfect operation for effective dry cleaning. Based on the consumable parts (brushes) that we continue to supply, many of these vacuum sweepers turn out to still be operational and have value as used.

Wetting sweepers: since the success of the suction carried sweepers, the market began to demand larger and larger machines, so it was impossible to maintain the suction system because the overall dimensions of the suction unit were not compatible with application on vehicles such as tractors, wheel loaders, skid loaders, trucks etc.

In 1998, strictly interpreting the Machinery Directive 98/37/EC for dust suppression, we completely redesigned the machine frames to integrate the water tanks into the frame itself and to maintain a low profile and allow better visibility to the operator, especially for applications on skid loaders, tractors with reverse drive and where the operator is in a particularly low position.